:max_bytes(150000):strip_icc()/graphite-steel-shafts-56a3d2235f9b58b7d0d3fefa.jpg)

How are steel golf shafts manufactured?

Graphite shafts are manufactured by wrapping sheets of graphite composite material around a steel mandrel. The composite sheets are cut into various sizes and shapes depending upon the design of the shaft. These cut portions are called flags.

How are shaft made?

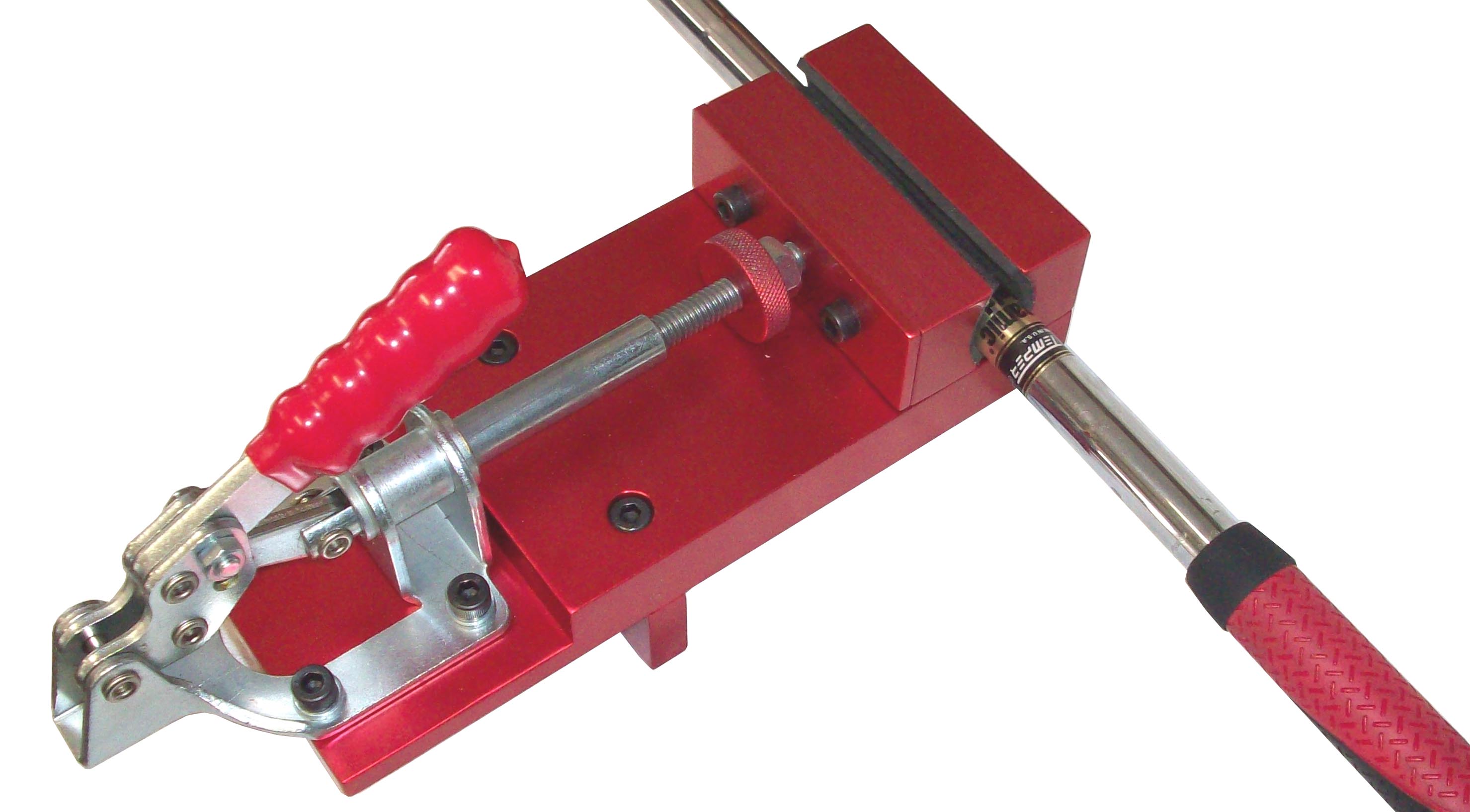

The most common process used to manufacture shafts is via CNC turning. Using this technique, workers or automated processes affix or clamp bars of materials to chucks and rotate them. While rotating, specialized tools use cutting and other subtractive processes to create and shape the end product.

What are iron shafts made of?

At the core, there are two types of golf shaft to choose from: steel or graphite.

What type of steel is used for golf club shafts?

– Steel shafts They are often made from carbon steel, but stainless steel is sometimes used, and start at 120 grams. Many players will benefit from having steel irons as torque or lateral twisting found in all graphite shafts doesn't occur in steel.

How do you make a golf club shaft?

1:3414:05How are Golf Shafts Made? - YouTubeYouTubeStart of suggested clipEnd of suggested clipWe cut flags for the tip section but section and some flags that run the entire length of the shaft.MoreWe cut flags for the tip section but section and some flags that run the entire length of the shaft. Depending. On the layup we can have up to 10 different kinds of materials in one shaft.

How is a golf iron made?

Cast golf irons are made through a molding process known as casting. In casting, a mold is made of the club head design the manufacturer is producing. The metal is then heated until it becomes a liquid and poured into the clubhead mold.

How do you tell if shafts are steel or graphite?

Weight. The most important difference between graphite and steel shafts is their relative weight. The typical graphite shaft is significantly lighter than its steel counterpart, which should translate into faster swing speeds.

Does Tiger Woods use steel or graphite shafts?

If you're considering a steel shaft in your driver or fairway woods, please consider a proper club fitting. A steel driver shaft is a thing of the past. Tiger Woods used a steel shaft in his driver, a True Temper X100, but moved away from it 20 years ago. Even competitors in the World Long Drive use graphite shafts.

Do pros use steel or graphite shafts?

In total 100% of the top 100 PGA Tour pros use graphite shafts in their drivers, fairway woods and hybrid clubs. 14 out of the top 100 use graphite shafts in their utility irons while 21 pros use steel.

What steel are golf irons made of?

All cast iron clubs are made from stainless steel. Stainless steel combines iron with nickel and chromium and other trace materials. Most good quality irons are made from either 17-4 or 431 grade stainless steel.

What is the best material for golf club shafts?

Graphite – this type of shaft is usually lighter weight compared to a steel shaft but it's less durable and more expensive to make. Graphite is one of the most common shaft types used in golf clubs and can arguably be considered the main shaft material used, beating out steel.

Do steel shafts have flex?

Golf club shafts come in five flexes and both graphite and steel shafts use the same system for determining flex. Because golf shafts bend during a swing based on how fast your club speed is, the faster your swing, the stiffer the flex you need.

How are axle shafts manufactured?

Steel axles are forged and heat treated via induction coils. By swiftly drawing the material through the electromagnetic coil, the heating and cooling of the material can be carefully controlled. In this way, engineers produce axle shafts featuring: Hard, solid surfaces.

How are transmission shafts made?

Shafts are made from mild steel. For the high strength shafts, alloy steel such as nickel, nickel-chromium, or chromium-vanadium steel is used. Shafts are usually formed by hot rolling and finished by cold drawing, turning, and grinding.

How hollow shafts are manufactured?

Hollow shaft is manufactured by defining a through hole axially in a shaft blank to produce a cylindrical hollow shaft blank, inserting a mandrel in the through hole of the hollow shaft blank, holding opposite ends of the mandrel concentrically with the through hole, and rotating the hollow shaft blank about its own ...

Which of the following method is used for making shaft?

4. Which of the following method is used for manufacturing shafts? Explanation: While the manufacture of products like shafts, discs or rings, the method of closed die forging or impact forging or flashless forging is not advised, but open die forging is used. 5.

How are graphite shafts made?

Graphite shafts are manufactured by wrapping sheets of graphite composite material around a steel mandrel. The composite sheets are cut into various sizes and shapes depending upon the design of the shaft. These cut portions are called flags.

What is a golf shaft made of?

Steel shafts are either pulled or rolled and welded. Graphite shafts are made with multiple layers of material wrapped around a mandrel.

What is a seamless steel shaft?

One is called "seemless" construction; the other is "welded tube" construction. A seamless steel shaft starts life as a large cylinder of solid steel.

What is it called when two ends of a coiled strip are fused together?

The welding procedure is quite different than what most people are used to seeing. Through what is called high-frequency welding, the two ends of the coiled strip are literally fused together without the presence of a second, different material as in the case of most welding.

The material of golf club shafts is usually made of graphite, steel, or titanium

Golf club shafts are made of graphite, steel, or titanium. They come in different lengths and flexes. The material is usually what dictates the price of the golf club shaft. If you want to be sure that your clubs will last longer than a year it would be worth paying more for a high-quality golf club shaft like steel or titanium.

Graphite shafts are more flexible than steel or titanium shafts

Golf club shafts are made of steel, titanium or graphite. Graphite is more flexible than steel or titanium and can be advantageous for golfers with a slower swing speed. Steel shafts are heavier than graphite but stronger, while titanium is lighter than steel but also strong. You want to choose the right material for your game!

Titanium has a higher strength-to-weight ratio than graphite but is heavier

Ever wonder what a golf club shaft is made from? Most golf clubs are made of graphite, but titanium has a higher strength-to-weight ratio and is heavier. The two materials have very different properties that affect the way you play your game.

Steel is less expensive than other materials but can be stiffer and heavier

Golf club shafts are traditionally made of steel. Steel is less expensive than other materials but can be stiffer and heavier. Composite shafts, which were introduced in the 1980s, have a lighter weight and lower cost than steel ones, but they break more easily and don’t hold up well in cold weather. The graphite shaft was invented in 1986 by Dr.

A golfer should choose which type of golf club they use based on their individual needs

It may seem like a simple question, but it can be difficult to answer. There are many different types of golf club shafts available on the market today and each type has its own benefits and drawbacks. Choosing which one is best for you will depend upon your personal preferences, playing style, and physical attributes.