How Golf Balls Are Made – Manufacturing Process

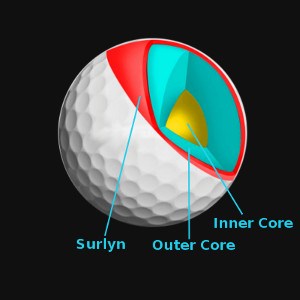

- Forming Ball Center. First, the manufacturer will mix the substances to create chemical reactions, resulting in a rubber compound.

- Outer Shell and Dimple Making. Once the central core is completed, the manufacturer will continue to give it a coat by injection or compression molding.

- Polishing and Painting. ...

- Logo Printing. ...

- Drying. ...

- Quality Test. ...

- Packing. ...

Full Answer

What companies make golf balls?

We Found The Companies That Make Red Golf Balls

- Titleist TruFeel Matte Red

- Callaway Supersoft Matte Red

- Taylormade Soft Response Red and Project

- Volvik Vivid Red Matte

- Bridgestone E12 Contact Matte Red

How can one make custom golf balls?

What You Can Expect From Us:

- A digital proof will be shared with you within two (2) business days

- Upon artwork approval, your customized golf balls will ship within 7 business days

- If logo/order is not approved within 45 days, your order will be cancelled and a refund will be issued.

- Note: All sales are final

How dangerous are golf balls?

Normal driving ranges simply can't contain Bryson DeChambeau anymore. Earlier this year, the RBC Heritage went as far as having two giant cranes holding a net above the existing one to keep the PGA Tour's longest player from hitting dangerous drives toward a road and Harbour Town's eighth green.

How to make money selling golf balls?

Where to Sell Used Golf Balls

- Overview. If you're a typical golfer, you have accumulated more used golf balls than you need. ...

- Practice Facilities. Visit local driving ranges to find out which ones buy used balls. ...

- Golf Courses. ...

- Flea Markets. ...

- Websites. ...

How are golf balls are made?

0:092:51How Do They Make Golf Balls? - YouTubeYouTubeStart of suggested clipEnd of suggested clipEarly golf balls were made by stuffing feathers into a leather sack or by molding latex from gutta-MoreEarly golf balls were made by stuffing feathers into a leather sack or by molding latex from gutta-percha trees. Most modern balls begin as a block of rubber which forms the solid core.

What are golf balls originally made of?

Wooden golf balls were used up until the seventeenth century, when the feathery ball was invented. The first "real" golf ball was known as a "feathery"golf ball. Basically, the feathery was a leather sack filled with boiled goose feathers, then stitched up and painted.

How many steps does it take to manufacture a golf ball?

The Manufacturing Three-piece golf balls are more difficult to make and can require more than 80 different manufacturing steps and 32 inspections, taking up to 30 days to make one ball. Two-piece balls require about half of these steps and can be produced in as little as one day.

What does it cost to make a golf ball?

It costs around 90 cents to make the average golf ball. The materials used in the ball and whether or not this is a small or large company will impact the overall pricing of the golf ball.

What is the liquid inside a golf ball?

Contrary to golf folklore, the liquid cores aren't dangerous. Titleist, for example, has used a salt water and corn syrup blend. Today's core is generally made from synthetic rubber -- which may be mixed with bits of metal, such as tungsten or titanium -- or a plastic-like material such as acrylate.

When did they stop making wound golf balls?

Remember, wound golf balls were popular prior to the 2000s and they were constructed with thread windings that wrapped around their cores.

What kind of paint is used on golf balls?

Painting Golf Balls. Choose how you want your golf balls to look. You can use acrylic paint and paint brushes, or spray paint for a more solid look of one color. Depending on the design, you may need to gather a lot of golf balls.

Where does Titleist get their materials from?

Some of the individual parts may come from China or Japan, but every club is assembled in the Carlsbad manufacturing plant, undergoing the tight scrutiny of Titleist's industry-leading quality assurance. Titliest also has a network of fitting centers in the US, the UK, and more.

How many golf balls are made a day?

In all, on average, Titleist produces 1 million golf balls per production day in those four facilities combined, with 80 percent of those balls made in the United States.

Why are Titleist Pro v1 so expensive?

12:4115:00Why Are PRO V1 Golf Balls So EXPENSIVE!? - YouTubeYouTubeStart of suggested clipEnd of suggested clipIf you prefer a firmer golf ball if you can track some 392s down then then fantastic go for it. But.MoreIf you prefer a firmer golf ball if you can track some 392s down then then fantastic go for it. But. There's really not too much difference here and you really do get what you pay for with a pro v1.

Are golf balls worth money?

Generally you'll be paid between 6 and 12 cents per ball selling them wholesale. If you're good at collecting, that can add up to hundreds of dollars daily. If you're not a diver, or you don't find more than a few hundred balls at a time, you might consider retailing the used golf balls yourself.

Are Titleist balls expensive?

Titleist golf balls stand out as being some of the most expensive on the market; however, they also offer some of the best performance.

Were golf balls made out of wood?

The first golf balls from the 14th Century were made out of wood, specifically beech, by carpenters using hand tools. They weren't perfectly round and it's safe to assume that they sucked. The 17th Century saw the slight design improvement of the featherie, a leather ball stuffed with bird feathers and stitched shut.

Are old golf balls worth anything?

Because of the age and the craftsmanship put into these balls they are among the ones that have the highest price tag of collectible golf balls. These balls are referred to as antique, and goes for sums upwards of +$5000! See example from eBay below.

When were dimples added to golf balls?

In 1905, an English manufacturer named William Taylor registered a patent for a golf ball dimple design. Before long, all golf balls featured dimples that would be more or less recognizable today. As ball technology advanced, so too did dimple science.

What were old golf clubs made of?

Early Golf Clubs (similar to today's wedges) and a putting cleek. After 1618, the Featherie golf ball was introduced which endured for more than 200 years. Club heads were made from tough wood such as beech, holly, pear and apple. Shafts were made from ash or hazel.

What Is A Golf Ball Made Of?

A golf ball is a spherical object that is used in the game of golf. It is mostly made of rubber, with a small core of hard material to provide a solid centre.

What Is the Manufacturing Process of a Golf Ball?

In the beginning, a golf ball is a solid piece of rubber that is shaped and then enclosed in a thin ball made of urethane or plastic. The entire production process includes:

THE EARLIEST GOLF BALLS

Golf is old, but a popular sport that was first played in Scotland around the year 1400. The earliest golf balls were made from a material called feathery mix. The feathery mix consisted of goose feathers and tar.

THE FEATHERIE GOLF BALL

Feather is a new golf ball that is designed to maximize distance, accuracy, and control. It does this by being the first and only golf ball on the market made with a liquid core. The liquid core provides superior aerodynamics and flight trajectory.

THE RUBBER GOLF BALL

This is a story about the first golf ball that was fashioned out of rubber. It was developed by Walter Hancock in 1848 and this invention helped the game of golf to take off.

How golf balls are made? The manufacturing of golf balls

Here we will tell you about the Golf ball construction in a step-by-step manner.

Quality of the golf balls

The maintenance of the golf balls’ quality is what companies do on the top verge. The reason behind this is the satisfaction of the buyers and maintenance of the player’s score.

Conclusion

Wrapping it up with some closing words. We hope that we have mentioned everything that one wants to know about how golf balls are made and their manufacturing process. This article must be of prime importance, especially for those who are related to golf strongly or are golf professionals and those who love to improve their knowledge.

Frequently Asked Questions

Generally, the construction of golf balls includes the usage of plastic and rubber. And if we take a two-piece ball specifically it will contain a rubber core and the outer covering of thermoplastic, i.e.

Types Of Golf Ball

When asking the question of how golf balls are made, you have to keep in mind that the process will vary depending on the type of golf ball and when it was made.

The First Golf Balls

It is widely accepted that the Scots invented golf but there isn’t an exact known date of when this occurred.

The Invention of The Rubber Golf Ball

Thanks to the featheries, golf quickly became a game that was reserved for the rich.

Types Of Modern Golf Balls

It is easy to see that, over the course of time, the golf ball has come a long way. However, even today, we see various types of ball.

How Modern Golf Balls Are Manufactured

If you are talking about a three piece golf ball then the manufacturing process is one that is incredibly complex.

Conclusion

Golf has been played for at least 700 years but there is evidence to suggest that similar games were played long before this.