Can a golf ball break tile?

When one of these off-target golf balls strikes your roof, the impact can easily break or move the roofing tiles or shingles. You might be able to see some minor signs of damage from the ground, however, golf balls often cause much more damage than homeowners realize.

How do you check if tiles are laid properly?

6 Ways to Check Tiling Work Without a HeadacheCheck the tiles yourself. ... Observe with your eyes. ... Use coins to measure equality. ... Rub with your hand or walk with your feet to test for flatness. ... Test by listening. ... Test the floor level using a crystal ball. ... Testing the slope by pouring water.

What does it mean when tiles sound hollow?

If you hear a lower-pitched or a hollow sound, this can indicate that tiles have debonded, or were never bonded, somewhere within the tile assembly. Large tile areas can be sounded with a chain. A low tone is not a cause for immediate panic, however.

Will hollow sounding tiles crack?

Whenever tile is bonded to concrete, movement in the concrete will cause cracks to occur in the tile layer.

Should I wet the tiles before laying?

The main idea behind soaking or wetting tiles before installing them is that the base of your tiles is porous and therefore has a lot of air inside. If you lay dry tiles directly on top of mortar or cement, the tile will stick initially but as time passes, it will most likely fall off.

Can you fix tile Lippage?

If you really have excessive tile lippage, then normally you might have to remove the affected tiles to perfectly correct the problem. However, if most or all of the grout joints are low, it is possible to fill them but it may not be a practical solution after all.

Do hollow sounding tiles need to be replaced?

ANSWER - Hollow sounding tile is not a defect per industry standards. Although a hollow sounding tile can be a symptom of a defect. If all of the floor sounds hollow or a portion of the floor sounds hollow, then it might be due to the materials and configuration of the tile assembly below.

How do you fix hollow tiles without removing them?

0:040:30How-To Fix Loose & Hollow Tile & Wood Floors without Removing or ...YouTubeStart of suggested clipEnd of suggested clipNew way to fix your floor without removing or replacing. Just drill and fill fix the floor is anMoreNew way to fix your floor without removing or replacing. Just drill and fill fix the floor is an extra strength adhesive that rebonds loose and hollow flooring.

Are hollow tiles a defect?

FUNCTIONAL DEFECTS 'Drummy' or hollow sounding tiles indicate a bond failure. According to AS 3958.1, this would be considered a functional defect where 20% or more of any individual tile is 'drummy', or not bonded.

What causes drummy tiles?

Drummy Tiles is a term used to describe loose or de-bonded tiles and often a hollow sound can be heard when those tiles are walked on or tapped with an object. This sound is an indication that the tile adhesive has failed or not enough was applied, allowing the tile to become loose.

What causes floor tiles to debond?

Insufficient adhesive coverage Gaps and air voids in the adhesive bed could lead to debonding of tiles as well as tiles being fractured when hit by falling objects or subject to impact and vibration.

Why are my floor tiles moving?

There are a few reasons why your floor tiles may become loose such as house movement or damaged grout, but the most common reason for them becoming loose is due to spot-bonding being used to install them.

How to tell if a golf ball is good?

Golf balls can wear out with time, but they’re built extremely tough for a reason. After all, a golf ball can be whacked so hard that it travels 211 MPH through the air, on a repeated basis, and doesn’t break apart. Compare that to tennis balls, which are swapped out after every nine sets.

How to clean golf balls?

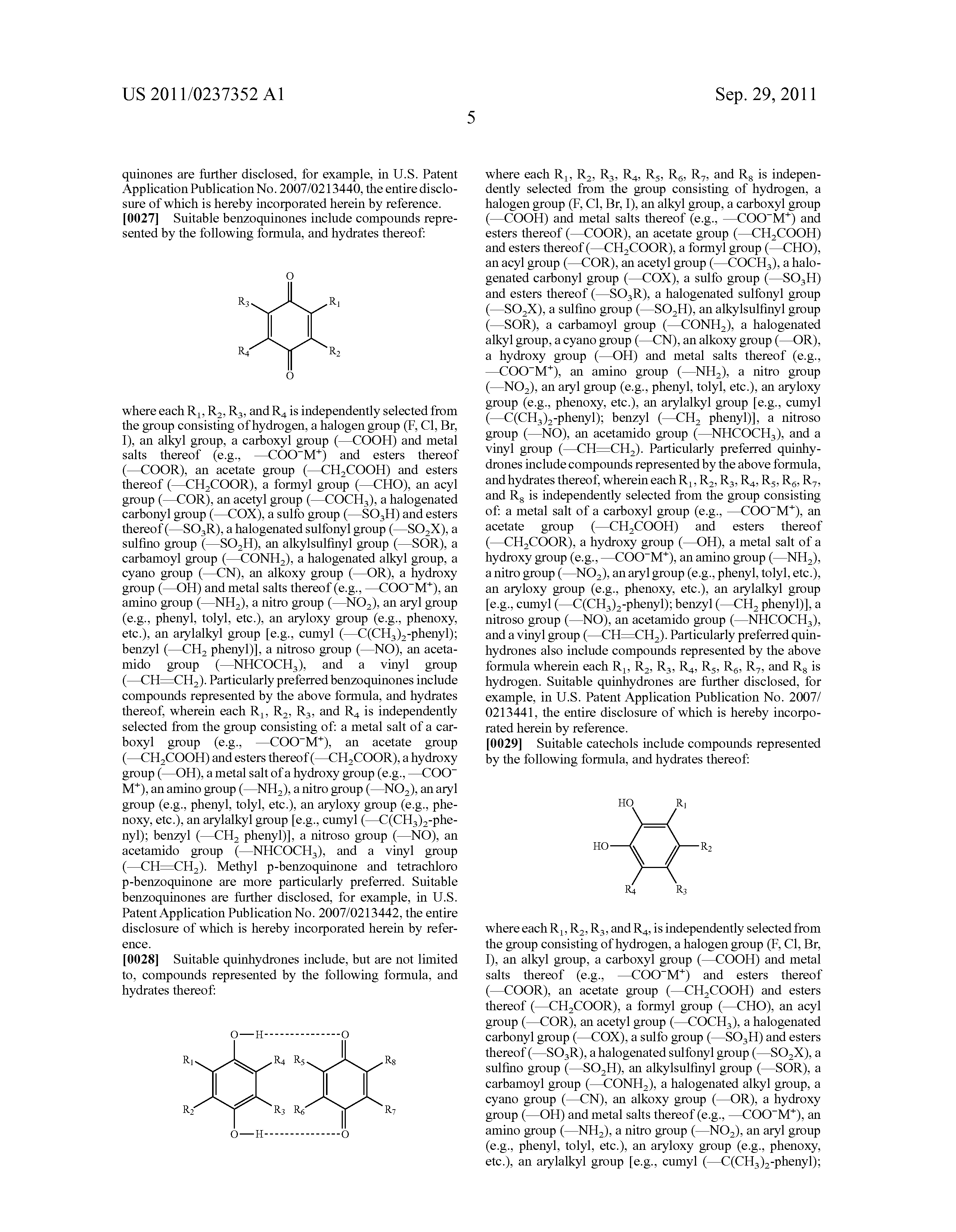

Using a soap solution, soak your golf balls for ten to twenty minutes. Remove them from the water and use a soft nylon or plastic bristle brush to scrub away any dirt and debris. Cleaning is important because excess grime can mess with the aerodynamics of a golf ball.

What does it mean when you can't hear a golf ball?

You want to be able to hear that. It’s the sound of vibrations rattling throughout the layers of your golf ball, and then reverberating off of the cover, which is usually made of some type of ethylene. If you’re not able to hear that sound, it means that there might be a microfracture somewhere on the cover’s surface.

What does it mean when a golf ball starts to sink?

If it starts to sink or you see any air bubbles coming up at all, it’s a sign that the cover has a microfracture. While these aren’t going to be visible like a full-on split (otherwise you would have already known that the golf ball is bad), it will be small and almost impossible to see.

Why do golf balls corrode?

That’s because UV rays from sunlight, which can be intensified by the water and act as a lens, will begin to corrode the ethylene cover of the golf ball. Since these bodies of water on golf courses are freshwater, there’s no lens of organisms to darken the water and prevent those UV rays from coming through.

Why do golf balls sink?

There’s a whole law of buoyancy, which is why golf balls will sink to the bottom of a freshwater lake on a golf course. If you have the opportunity, you need to get a couple of cups of seawater, or make your own using a beaker and carefully measuring out salt to make a seawater equivalent.

How fast can a golf ball travel?

There are a few things you can do to test your golf balls. Since most are made to handle enough force to travel over 130 MPH (the record being 211 MPH), they’re more resilient than you think. Try these quick and easy tips out to see if they’re still functional.

Got loose, tenting or drummy tiles? The first step is to help us diagnose the extent of the damage

NEED HELP? Follow these quick tips to help more accurately diagnose the problem before we come out to inspect your property.

Step 1: Diagnosis

Grab a golf ball (if you can find one) and bounce the ball on each of your tiles. You will be able to hear the difference between a sound tile and a de-laminated tile.

Step 2: Counting

Count the number of tiles that sound hollow or somewhat hollow. Make a note of which areas of the house/area are hollow- as this will help identify where there may be a risk of spreading.

Step 3: Checking for Expansion Lines

Check your floor area- are there any grout lines that appear larger or wider than the rest?

Quantifying Golf Ball Quality

One of the many insights gleaned from last year’s ball test is that every ball has two sets of specifications. Most every golfer focuses on the performance spec: speed, launch, spin – stuff we can all see to some degree. Seldom, it seems, do golfers consider the quality spec.

Model 55-M Golf Ball Compression Tester

While there’s no standard-issue compression tester, the OK Automation 55-M is widely used across the ball industry. Not only will it allow us to identify which balls offer the most consistent compression by measuring every ball with the same tool, we can reliably compare compression across models and brands without relying on OEM numbers.

Model 95-M Diameter Measurement Gauge

Effectively a size gauge, the 95-M will allow us to take diameter measurements and determine roundness. If a brand struggles to produce golf balls that are actually round, we’re going to tell you about it.

Ohaus Pioneer PX 323 Precision Electronic Balance

Accurate to within 0.001 g, we’ll use the scale to verify weight conformity while also tracking the weight consistency of each model we test.

Milwaukee M12 Cordless PVC Cutter

The workhorse of #FindItCutIt, we’re going to keep using the M12 to cut golf balls. We’ll cut a random selection of balls from each dozen and grade them for centeredness and layer concentricity.

Consistent Measurement

To maintain consistent environmental conditions for testing, balls will be stored in a temperature-controlled humidor at 70 degrees with 50-per-cent relative humidity.

Retail Balls Only

To ensure everything is on the up and up and nothing gets pre-sorted on its way to us, MyGolfSpy will purchase all of our test balls at retail. The plan is to test three dozen of each model. All 3 dozen will be cut for further analysis.