What Is a Forged Iron?

- Creation. Forging techniques differ between club manufacturers, but the basic idea of forging has been around for centuries – metal is heated up, then hammered or pressed into shape.

- Evolution. Forged irons were the only option for high-level golfers for most of the 20th century. ...

- Advantages. ...

- Game Improvement. ...

What are the best golf irons for beginners?

May 06, 2022 · Forged Irons are made of a higher quality steel than non-forged ones, which allows them to be shaped more precisely (on both machines and by hand) before they are finished with high-polish processes. This also gives them better overall weight distribution throughout each clubhead – an important factor in mis-hit shots.

What does forged mean in golf irons?

Oct 15, 2018 · The definitions of what cast and forged mean have definitely changed over the years. The traditional one-piece iron, which was the only design available in the past, didn’t …

What are the most forgiving Forged irons?

Tour player like Bill Haas prefer forged clubs. There are two different methods of making golf irons. Traditionally, club makers forged a club head by heating a piece of iron and manually …

What are the most forgiving straightest Irons?

A forged iron contains a clubhead that’s heated and molded from a single piece of metal. Unless you’re an expert, you probably won't be able to look at an iron and determine whether it’s been...

Are forged golf irons better?

What is the advantage of forged irons?

Why are forged clubs better?

Are forged irons good for high handicappers?

Do pro golfers use forged irons?

Are forged clubs harder to hit?

Are forged irons the same as blades?

What are the easiest forged irons to hit?

- Callaway Epic Forged.

- Cobra King Forged TEC.

- Mizuno JPX921 Forged Iron Set.

Which is stronger forged or cast steel?

What type of iron is used in the Ping i500?

This is particularly important, because multipiece irons — like those with flexible face inserts — often require a variety of methods to produce. As such, the question of forged or cast in irons is really not something most players need to worry about. The new Ping i500 irons feature a forged C300 maraging-steel face.

Can you make one piece iron?

The traditional one-piece iron, which was the only design available in the past, didn’t have flexible face inserts , vibration-dampening technologies , or additional high-density weighting. As such, you could build them by casting or forging them, and people chose them primarily by look and feel.

What are forged irons made of?

They were made of softer steels and had other features such as less hosel offset and thinner top lines that appealed to professionals and better amateurs who appreciated the superior feel and ability to shape shots. The cost of making forged irons was higher than for their cast counterparts.

What is the preferred iron for golfers?

Other manufacturers switched their process to casting and, eventually, stainless steel investment cast irons were the preferred choice of most golfers.

When did Ping irons start making golf clubs?

All golf irons were forged until the late 1960s when Ping began producing irons with a revolutionary cavity back design. By positioning the club’s weight around the periphery of the club head, Ping designers made them more forgiving of off-center hits. They found that the new head shape was much easier to make using a method called investment casting. This also allowed them to switch the club head material to stainless steel, which is harder and more durable than the carbon steel used in forging.

When did forged irons begin to evolve?

In the 21st century, the design of forged irons began to evolve.

When did golf irons start being cast?

In the 1970s, the casting process started to become popular and by the 1990s most golf irons were cast by pouring molten metal into pre-formed molds. In 2010, manufacturers still use both of these processes to make forged and cast irons.

Why use a forged iron?

Because a forged iron is constructed from a single piece of steel, a forged clubhead is more consistently solid than a cast-iron club. The casting process inevitably creates tiny air bubbles that are trapped in the mold and become part of the finished clubhead. Highly skilled golfers tend to prefer the greater feel they receive with forged irons, which typically allow top players to produce more accurate shots, provided they hit the forged iron’s smaller sweet spot in the middle of the clubface.

What are forged irons made of?

The main alternative to forged clubs are those made from cast irons, which are made by pouring hot liquid metal into a mold and allowing the metal to cool. As casting techniques and designs improved, cast irons gained greater popularity, largely due to the development of “game improvement” clubs that were more forgiving of mis-hits. By the mid-1990s, only about half the players on the PGA Tour were using forged irons. In the 21st century, however, many forged irons incorporate design ideas made popular by cast-iron clubs. Even some cavity-back clubs, formerly the sole province of cast-iron manufacturers, are now being forged. As of 2010, approximately 80 percent of PGA Tour golfers carried forged irons in their bags.

How is a club forged?

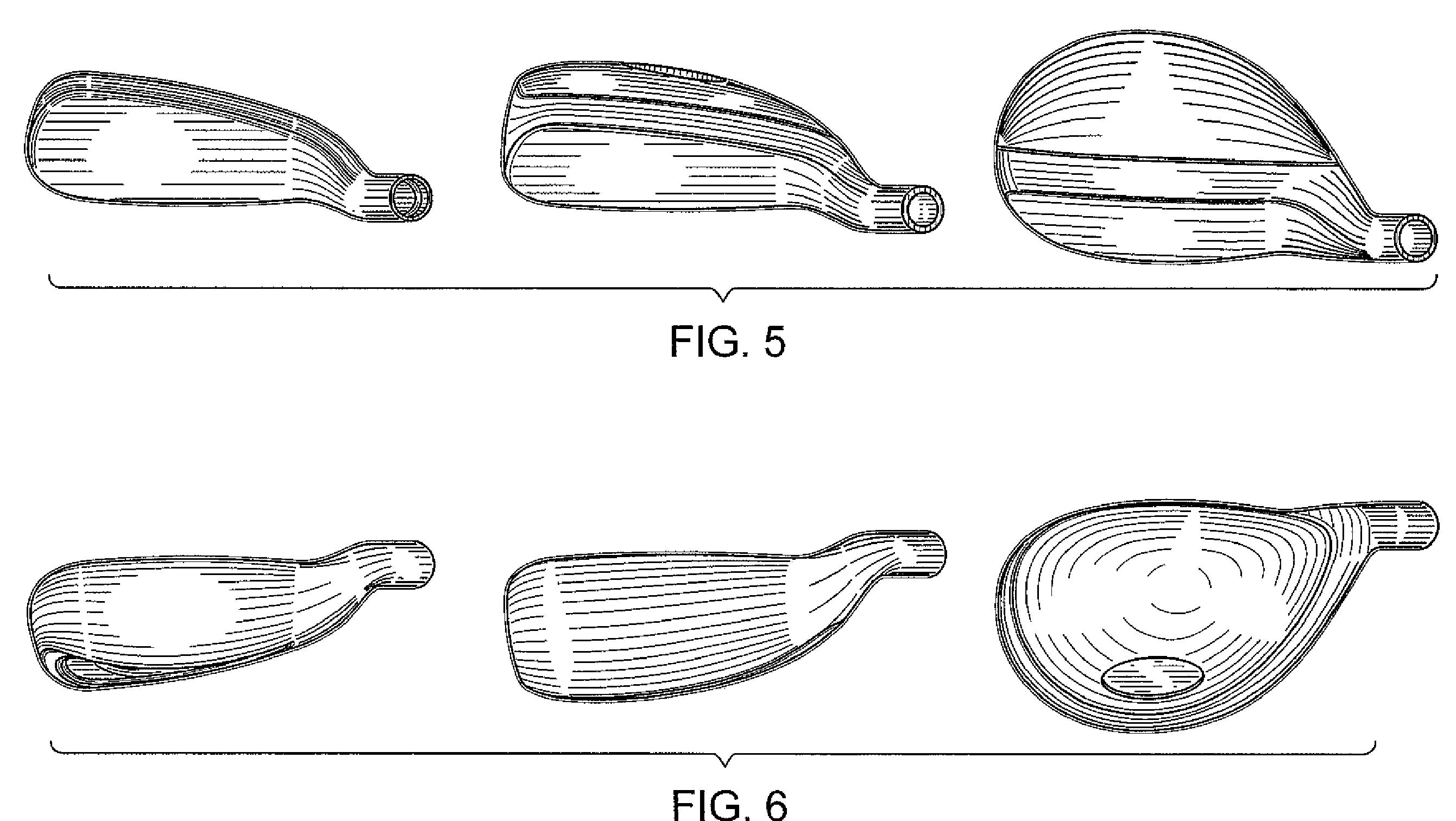

Forging techniques differ between club manufacturers, but the basic idea of forging has been around for centuries – metal is heated up, then hammered or pressed into shape. For example, the process used by Mizuno – which has been forging clubs since the 1930s – begins with a bar of 1025 or 1025E steel that is heated to a red-hot temperature. The steel is bent into the correct angle for the particular club being made, then placed in a primary forging mold, where an air hammer presses it into its basic shape. After another machine trims the excess metal from around the edges, the future clubhead is re-heated and placed into a second mold, where the metal is pressed slowly to create the final shape, including the grooves. The clubhead’s sides are then smoothed on a grinder before it’s attached to a shaft.

Why use game improvement clubs?

The average golfer will benefit from using game-improvement clubs, many of which are still manufactured using the casting process. Game-improvement clubs have larger sweet spots , are more tolerant of mis-hit shots and give beginning golfers a better chance to hit with reasonable accuracy.

What is the process of forging a golf club?

Boyd says: “The forging process is taking a solid billet of steel, and then through various steps, using heat, pressure, and tooling dyes to refine it into a part that can be used for golf clubs. And in the process of forging a golf club, the grain structure — the internal structure of the metal — is further condensed. … [Forging is] really the most time-consuming and expensive way to manufacture golf clubs … with cast, you’re taking something liquid, pouring it into a mold, and then it’s cooling in that mold.”

Is it cheaper to cast or forge golf clubs?

It’s a lot simpler to tool and a lot less expensive to tool and produce cast golf clubs. When you’re forging … you have several dyes that you’re going through in the process. There are a lot of steps, and it’s very expensive to tool a forged golf club.

What happens when you forge a golf iron?

The forging process: When a golf iron is forged, the solid metal of the clubhead is literally pounded or compressed until it takes the desired shape.

What is a forged iron?

The first thing to know is that "cast" and "forged" are nothing more than terms describing the manufacturing process of an iron or set of irons. The casting process: When a golf iron is cast, the metal used to make the iron is heated to its melting point, becoming a liquid. It is then poured into molds of the iron heads.

How are golf irons made?

Golf irons are made one of two ways: by casting or by forging. Golfers shopping for new irons may encounter advertising touting "forged irons" or see others referred to as "cast irons.".

How do you make a golf iron?

The casting process: When a golf iron is cast, the metal used to make the iron is heated to its melting point, becoming a liquid. It is then poured into molds of the iron heads. When it cools and hardens, voila, you have golf irons.

What is the purpose of casting in golf?

The casting process, when it was invented, allowed golf manufacturersto build in "game improvement" features such as cavitybacks, wider soles, and so on, to create more perimeter weighting and higher MOI, to experiment with center of gravity locations.

Do forged irons feel softer than cast irons?

That is, that forged irons have a noticeably softer feel at impact with the golf ball than do cast irons. But it that true?

Can you use forged irons as shorthand?

So if you're shopping for golf clubs and you see a club marketed as a forged iron, you can use that as shorthand to know that it is probably aimed at, and best-suited for, lower-handicap golfers.

What is the difference between forged and cast iron?

Firstly, the main difference between cast and forged irons is the actual process of manufacturing. With cast irons, the manufacturing process is called the “investment casting” or “lost wax” process. In this process, a wax model of the club head is made and then this model is coated with a ceramic mixture. Once the ceramic mixture is hard the ...

How are forged clubs made?

So, now let us look at the process for forged clubs. Then we will do a comparison of forged versus cast. In the forged process, a solid billet of steel is used. The steel billet is heated to very high temperatures, put in a press and is then hammered into shape with several tons of pressure. This process can be repeated several times before the head is ready for finishing. It is at this point that there is a big difference between cast and forged. With the cast process, at this point the head is virtually ready to be assembled. There is not very much additional work to be performed on it. In the forged process, the head has to go through a grinding, buffing and detailing process before it is ready to be shafted. This part of the process requires very skilled craftsmen and is extremely labor intensive. The cost of labor is the main reason why forged clubs are much more expensive. There are a few smaller foundries in Japan that are still producing totally hand forged heads, and they are the priciest heads available. They produce beautiful heads. They are of top quality but you pay a premium price for them.

How do forged clubs compare to cast clubs?

The main difference in the two methods is this: in a cast process, there can be small air bubbles that are created in the process and when cool turn into tiny voids, whereas in forged clubs this does not occur, the metal is solid throughout. If you are a visual person, think of it this way: the molecular structure of a cast head is like a jar of marbles (beads) whereas with a forged head it is like a jar of fine sand, much denser. But does this affect the playability? In a word, “no”. For some players it is all about the feel. For lovers of forged clubs, the impact feels and sounds more solid. For the average golfer, I do not think they would feel any difference at all.

Why are forged clubs so expensive?

This part of the process requires very skilled craftsmen and is extremely labor intensive. The cost of labor is the main reason why forged clubs are much more expensive.

How many degrees should forged clubs be?

One instance where forged clubs might be a necessary option is when it is determined in the fitting process that the golfers set up or his general swing characteristics require that the lie angles be markedly upright or flat, more than 2-3 degrees.

What is the advantage of casting over forged?

The advantage that cast heads have over forged heads is in the level of design possibilities. In the cast process, there is really no limitation on design. In forged clubs, there are limitations. I doubt we will ever see a forged head with a huge undercut cavity and extra wide sole.

What type of metal is used for investment casting?

There is no restriction as to what type of metal can be used. In the early days of investment casting, a grade of steel called 17/4 stainless steel was used which when hardened was extremely hard and brittle.

What is forged iron made of?

Forged Irons. Forged irons are typically made from a single piece of steel. There are different techniques for making forged irons, but in all cases the steel is heated, then molded into shape by at least one large pressing machine.

What are cast iron clubs made of?

Cast-iron clubs are made from liquid metal that’s poured into a mold, then allowed to cool. The process makes it easier to manufacture clubs in a variety of shapes. This technology led to the introduction of cavity-back clubs, which have thick ridges around the rear perimeter of the clubhead, leaving a cavity in the middle. Cavity backs are typically listed as “game improvement” clubs because their technology helps most amateur golfers improve their games, mainly by being more forgiving of mis-hits.

Why use a cavity back iron?

The weight of a cavity-back clubhead is more evenly distributed around the perimeter, making cavity backs a better choice for weekend golfers because the clubs are much more tolerant of mis-hit balls. Beginning golfers in particular will find it easier to hit the ball straight with a cavity-back iron.

Is a cavity back iron forged?

The battle lines have blurred recently, as some cavity-back irons are now forged, leaving the golfing consumer with a variety of choices.

Can you hit a golf ball straight with a cavity back iron?

Beginning golfers in particular will find it easier to hit the ball straight with a cavity-back iron. The bottom line is that two identically designed clubs will show little or no performance differences, whether the clubhead is forged or cast.