How long does it take for epoxy to work on golf clubs?

A quick-cure epoxy is recommended only if you want to use your golf club in about an hour. In other words, this epoxy is best suited for emergency fixes only. Because of this, the epoxy is also referred to as the five-minute epoxy. On the other hand, a long-cure epoxy or 24-hour epoxy takes about 20 hours for the bonding to be effective.

How long does it take for epoxy to dry?

While some epoxies take five minutes, a few others take close to a day. The surrounding temperature also affects the curing process. Curing takes place faster in warmer temperatures. On average, the curing of golf epoxy may take about 12 to 18 hours to get dry on a warm day.

Can you use epoxy to install a golf shaft?

Using epoxy to install a shaft is not a difficult task, but I think some people get a bit confused when dealing with different types of golf clubs. Putters are fairly easy to do, but when re-shafting irons and woods, we have to install the ferrule as well, which is a bit confusing to the novice.

Is 5 minute quick cure golf epoxy any good?

However, it is always a good idea to stay away from 5-minute quick cure epoxies even if they have a two-component formulation. How Much does Golf Epoxy Cost?

How long does golf epoxy take to cure?

The High-Strength Epoxy is a 1:1 mix ratio, sets in 18 hours and cures in 24 hours. Available in 50ml cartridge for easy application.

How long does TOUR SET epoxy take to dry?

60-90 minutesTour Set Epoxy combines the strength of long-cure epoxies with the conveniences of shorter cure epoxies. Tour Set has a gel time of 12 minutes. Cures to playing strength in 60-90 minutes, depending on temperature. Also available in 50 ml.

How do you epoxy a golf club shaft?

4:044:48Hireko Golf Videoblog "Tips on Epoxying a Golf Club" by ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipWe're in the head I just simply use the shaft. And just roll the shaft tip in and then mix it andMoreWe're in the head I just simply use the shaft. And just roll the shaft tip in and then mix it and just put it in in the head.

Is JB Weld epoxy good for clubs?

Jb Weld can be used on both metal and plastic golf clubs. It is non-toxic and safe to use on most surfaces.

How do you know when epoxy is cured?

The epoxy passes into an initial cure phase when it begins to gel, or “kick-off.” The epoxy is no longer workable and will progress from a tacky, gel consistency to the firmness of hard rubber, which you will be able to dent with your thumbnail.

How long does 2 part epoxy take to dry?

Two Part Epoxy Curing Time Full cure of a two part epoxy can be several days. However adequate strength for further assembly, or packaging can be reached within minutes or hours. To increase full cure speed, heat can be used.

How strong is golf epoxy?

What Epoxy PSI Number Should You Use. Ideally, your golf epoxy should have a PSI number of over 2500 PSI. The GolfWorks shafting epoxy is a great option because of its high torque resistance and shear strength. The epoxy renders 90% curing to 2765 PSI in a day and 100% curing to 3280 PSI in a week.

Will any epoxy work on golf clubs?

Unless you have to, do not use non-golf specific epoxies. Use epoxy designed for golf as they usually have higher peel sheer strengths and elastic properties that hold well during impacts specific to a golf club hitting a golf ball.

What kind of epoxy is used on golf clubs?

Permabond offers a range of toughened epoxy adhesives which are suitable for bonding golf clubs. They offer excellent adhesion to carbon, graphite, composite, titanium, steel, wood and many other materials. Cure speed and viscosity can be matched as per the user's preference.

Can you use JB Weld for golf shafts?

JB Kwik Weld has a 2451 psi which is just about perfect strength for a golf epoxy and heat tolerance of 230 degrees. The best part is it has a 6 minute working time, 1 hour harden time, and 6 hour cure time.

What glue is used for golf shafts?

Golf club heads are attached to the golf shaft with epoxy glue. Epoxy is a thermosetting polymer that is a high strength adhesive. Two parts, the resin and the hardener, are mixed together to create a chemical reaction that cures the epoxy to hardness.

How strong is 2 ton epoxy?

2 Ton Epoxy sets in 30 minutes with strength up to 2,500 lbs. per square inch and is available in a 1 oz set (total weight divided into 2 tubes).

Can you dry epoxy with a hair dryer?

You can use a blow dryer or hair dryer to dry your resin art fast. To do this, simply plug in the dryer and blow it directly onto your resin art. But be cautious to not blow too hard and too warm.

How long should epoxy cure before sanding?

Tip: The epoxy resin must be really dry before sanding. You should therefore allow a waiting period of at least 48 hours before processing. Follow the manufacturer's instructions, as there are resins that take even longer to harden completely.

How long does 5 Minute epoxy take to cure?

45 minutes to 1 hourCure time for 5-Minute Epoxy Gel is 45 minutes to 1 hour for a functional cure. Full bond strength is reached in 16 hours @ 24°C. Devcon Epoxy Adhesives should be stored in a cool, dry place when not used for a long period of time.

What temperature does epoxy need to cure?

between 65-80 degreesCuring Epoxy in The Right Environment Now, let's talk about room temperatures. The ideal room temperature for working with epoxy resin is between 65-80 degrees. These are perfect temperatures for your epoxy to cure to a perfect result, and for the two chemicals to combine seamlessly.

What is an Epoxy for Golf Clubs?

A golf club epoxy is an organic compound that is a type of glue that can be used on golf clubs, to attach a shaft to the clubhead. Knowing how to use a golf club epoxy can be beneficial when your clubs need a quick repair job.

Types of Epoxy used for Golf Clubs

Epoxy adhesives for golf clubs can either be a quick cure epoxy or a long cure. Both adhesives are two-component based. Normally an equal quantity of each component is mixed together.

Golf Club Epoxy vs. General-Purpose Epoxy

Most epoxies will do the intended job but non-golf or General- purpose epoxies that can be purchased at any hardware store, are not recommended. They are not engineered specifically to withstand the unique forces generated by the golf swing. They tend to be brittle resulting in poor peel and impact resistance.

Curing of Golf Club Epoxy

The temperature of the room where the epoxy is being applied and where it will be left to cure is critical to ensure that the epoxy cures properly.

1. J-B Weld 8281 Professional-Size Steel Reinforced Epoxy Twin Pack – 10 oz

The J-B Weld 8281 has a very high tensile strength of 5020 psi that can withstand all the forces exerted from swinging a golf club.It is resistant to acid, water and, cracking from high impact and is very durable and, has a high heat tolerance

4. Permabond Epoxy For Golf Clubs

Easy mixing from the cartridge ( various sizes dependant on the product used) with a static mixing nozzle.

Final Thoughts

If the steps required to fit a shaft to a clubhead are followed correctly then you can easily and correctly fit your selected shafts without having to send them in to be fitted thus saving you unnecessary costs.

Series Navigation

Using epoxy to install a shaft is not a difficult task, but I think some people get a bit confused when dealing with different types of golf clubs. Putters are fairly easy to do, but when re-shafting irons and woods, we have to install the ferrule as well, which is a bit confusing to the novice.

Series Navigation

Hey!! I'm Zach, the founder of The DIY Golfer. I created this site in 2015 while playing D1 collegiate golf to help myself understand the game of golf better and improve as a player. Fast forward a few years, and it has become much more than a journal.

Why use fast setting epoxy?

The fast setting epoxies, due to their quick setting time, are more brittle and can have a higher failure rate if precautions are taken. For new clubmakers, we feel it is best to start with slow setting epoxy to avoid being rushed and having an epoxy failure. If you do decide to use fast setting epoxy, then mix enough for small batches.

What is fast curing epoxie?

Chemical manufacturers are able to produce higher shear strength, fast curing epoxies, which appeals to clubmakers as an effort to save time during the assembly process and to establish a rapid turnaround time for their customers in this day age.

Can fast curing epoxy be used in club making?

The use of fast curing epoxy may appear to be a time saver but could end up costing you more time and potential embarrassment with customers if the epoxy bond were to fail. So, you need to weigh the risk. Most clubmaking shops will carry both types of epoxy and use in the appropriate situation.

How long to mix epoxies for golf drivers?

These epoxies are great for when you are building multiple golf drivers in one sitting. Likewise, the 5 minute, 10 minute and other quick cure epoxies tend to have lower overall sheer strength and mixing times. These quick epoxies have very short mix times and are not recommend when building more than 1 or 2 golf clubs or golf drivers at one time.

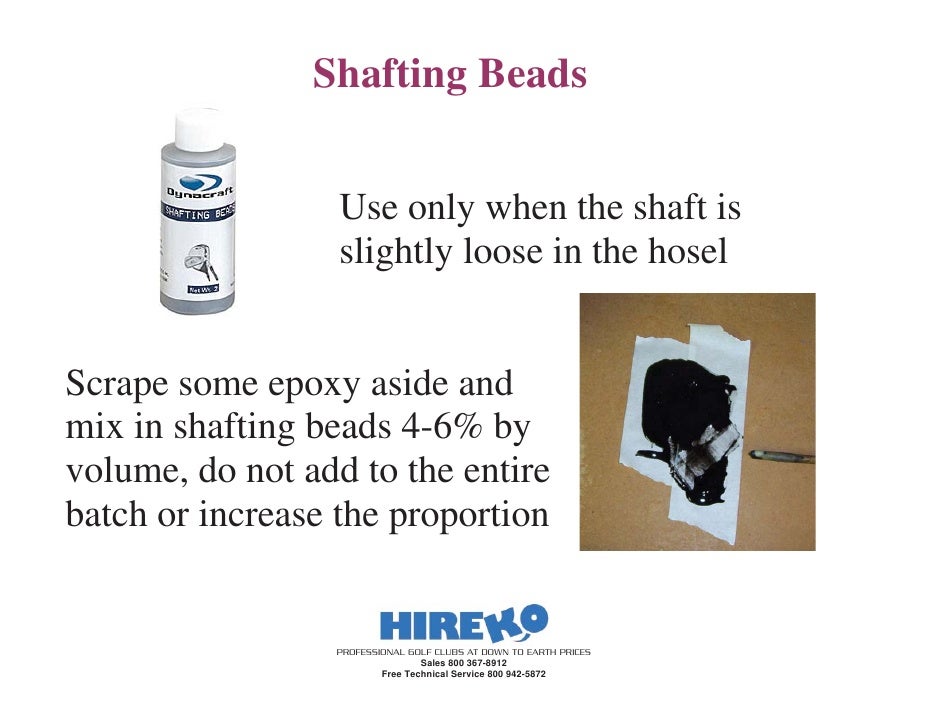

Can you use glass beads on epoxy?

Yes... the secret to making any epoxy stronger and increase the strength and adhesion is to add glass shafting beads. A small pinch of these beads will help increase not only strength but will help center your golf shaft in the hosel. It is recommended to use the shafting beads in all golf driver or golf club builds!

Can you mix more than one golf club at a time?

These quick epoxies have very short mix times and are not recommend when building more than 1 or 2 golf clubs or golf drivers at one time. The shorter dry time epoxies are appealing to golfers that want to build and hit their new clubs the same day, but I always recommend the longer cure epoxy for longevity of the club.

Can you use non-golf specific epoxies on golf clubs?

Unless you have to, do not use non-golf specific epoxies. Use epoxy designed for golf as they usually have higher peel sheer strengths and elastic properties that hold well during impacts specific to a golf club hitting a golf ball.

Can you use non-golf epoxies on a golf swing?

Although these will most likely hold for most applications, they are not recommended and engineered specific to unique forces that a golf swing cause. Unless you have to, do not use non-golf specific epoxies.

Do epoxies hold longer?

First, let me say that the majority of epoxies will do the intended job well. But with this said, there is varying levels of quality, sheer strength and cure times. As a basic rule of thumb, the longer the dry or cure the time the higher the strength or hold. The longer dry time epoxies, also known as 24 hour epoxies typically offer longer times ...

Feedback

24 hrs. is always a safe rule of thumb. You could probably get away with playing them sooner, but it's not worth the risk of having the head fly off in the middle of the driving range, which I have seen happen before.

Feedback

Likewise. The epoxy used makes the rule as to curing time. Personally I use 5 min. epoxy on my clubs and am confident therein but club makers need to satisfy their customers and so will use either 12 or 24 hour epoxy. Talk to your club maker. Shambles

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

Does epoxy work on composite shafts?

In addition you will ensure that excess epoxy does not work its way up inside the shaft tip (especially on composite shafts) and prevent potential breakage. Shop Golf Shafting Epoxy.

Can you use too much epoxy on a golf club?

Getting “just the right amount” of golf club epoxy on the shaft tip and coating the inside of the hosel is a delicate – and critical – part of golf club assembly. Beginning clubmakers generally tend to use too much epoxy to start, but learn to cut back after a few messy clean-up jobs. It is important to understand that using too much epoxy can do ...

Erik-M

so the question is... Does anyone have problems with golf shaft epoxy failing? I've had the same club head come loose twice now. Can't really see a reason why it would be failing. The club head seems as clean as the rest inside the hosel. I don't hit that club anymore that any other club.

hckymeyer

Typically when this happens it's either because the hosel and shaft weren't cleaned and prepped properly, or the epoxy wasn't mixed properly. Was the same epoxy used through out the entire set? Or you mentioned it's the 2nd time this happened to the same iron, could have just been a bad ratio or mix if it was a one off rebuild.

Erik-M

Initially the entire iron set was done at the same time, used shafting beads in the entire set also. After the first time it failed Michael Riley reshafted it on his own but I would assume he used shafting beads then too.

Erik-M

I will clean the hosel to the nth degree when I reshaft it in the next day or 2

Erik-M

Is there any good epoxy to grab from Walmart or do you need to stickk to golf epoxies?

bens197

Is there any good epoxy to grab from Walmart or do you need to stickk to golf epoxies?

Tom the Golf Nut

Also make sure there isn't a build up of epoxy in the shaft tip. If so drill it out. You need a way for the air to escape up the shaft when you insert the shaft into the hosel.