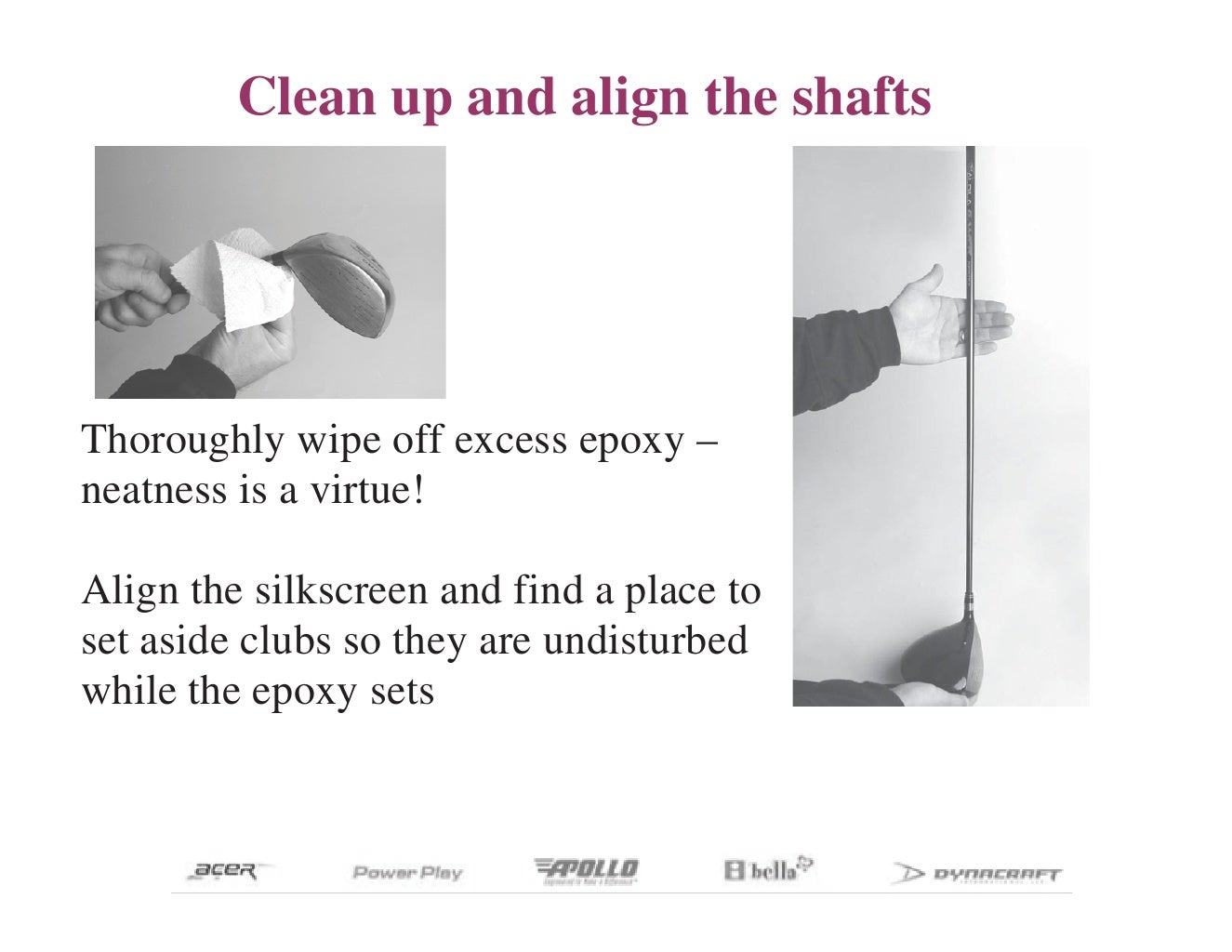

Before you use a golf epoxy for your golf club, you should know how much epoxy you will need to use. All you need to do is to coat the shaft tip and the complete surface inside the hosel separately with a thin and even layer of the epoxy. This will usually be less than 0.5g. A drop is more than enough for the shaft tip.

Full Answer

What is the best epoxy to use for golf clubs?

All of the golf specific epoxy's regardless of cure time should work just fine if mixed properly with the right ratios. Assuming of course that the work was done properly :) BB More sharing options... I've used Bramptons, Golfworks and Diamond Tour epoxies all with no failures.

How long does it take for golf epoxy to cure?

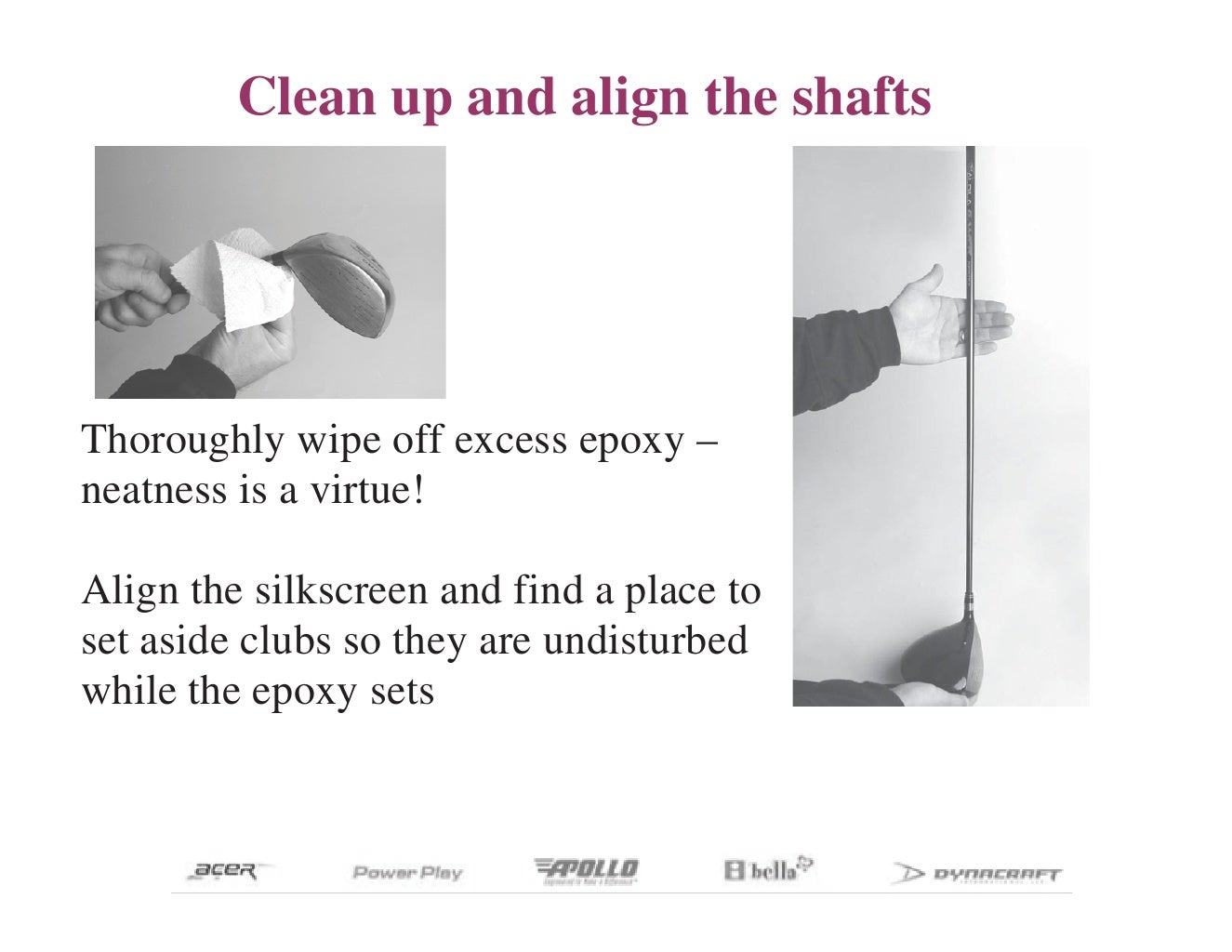

Make a marking on the shaft at 1/8 th of an inch below the preferred playing length to extend the length of the golf club. Ideally, there is no fixed time for your golf epoxy to get cured.

Why are golf epoxies so expensive?

One factor is the components used in the epoxy formulation. The other factor is the brand of the adhesive. In general, golf epoxies are not an expensive deal.

How much does golf epoxy adhesive cost?

The other factor is the brand of the adhesive. In general, golf epoxies are not an expensive deal. You can get well-known ones from a golf clubs repair store in your neighborhood or online stores like Amazon for a nominal price ranging between $6 to $12.

How long does Tour set epoxy take to dry?

60-90 minutesTour Set Epoxy combines the strength of long-cure epoxies with the conveniences of shorter cure epoxies. Tour Set has a gel time of 12 minutes. Cures to playing strength in 60-90 minutes, depending on temperature. Also available in 50 ml.

How long does Golf shaft epoxy take to set?

When it comes to epoxy, clubmakers have a choice between slow and fasting curing epoxies. Slow cure epoxy typically fully cures to safely hit a ball in 20 to 24 hours at a normal room temperature. On the other hand, fast curing epoxy can come to full cure in approximately 30 minutes.

What epoxy is best for golf clubs?

Best 4 Epoxy Adhesives for Golf ClubsJ-B Weld 8281 Professional-Size Steel Reinforced Epoxy Twin Pack – 10 oz. View on Amazon. ... Brampton Epoxy Pro-Fix 20/20 Long Cure Golf Club Repair. View on Amazon. ... GolfWorks High Strength Epoxy Golf Club Head Shaft Adhesive 50 ml. View on Amazon. ... Permabond Epoxy For Golf Clubs.

How long does it take for golf epoxy to cure?

The High-Strength Epoxy is a 1:1 mix ratio, sets in 18 hours and cures in 24 hours. Available in 50ml cartridge for easy application.

How do you epoxy a golf club shaft?

4:044:48Hireko Golf Videoblog "Tips on Epoxying a Golf Club" by ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipWe're in the head I just simply use the shaft. And just roll the shaft tip in and then mix it andMoreWe're in the head I just simply use the shaft. And just roll the shaft tip in and then mix it and just put it in in the head.

Can you use regular epoxy for golf clubs?

Unless you have to, do not use non-golf specific epoxies. Use epoxy designed for golf as they usually have higher peel sheer strengths and elastic properties that hold well during impacts specific to a golf club hitting a golf ball.

How long does it take to get a golf club Reshafted?

It takes 24 hours to reshaft a golf driver. The actual time depends on the epoxy used for this process. If you use an epoxy such as the Tour epoxy, you can get done with the reshafting process really fast and your driver will be ready to use in about half an hour.

Is JB Weld good for golf clubs?

Jb Weld can be used on both metal and plastic golf clubs. It is non-toxic and safe to use on most surfaces.

How long does it take for Tour Set Plus to gel?

Tour Set Plus offers all the convenience and long lasting bond of standard Tour Set, but with a gel time of just 25-35 minutes for added convenience. Cures to playing strength in 60 to 90 minutes, depending on temperature.

Is Tour set epoxy good?

The Tour set epoxy has excellent sheer strength and a workable set time. There is less waste than some of the "quick set" epoxies (i.e. 5/15) I have tried. I have never had the head or ferrule seperate, using this Golfworks product.

How to apply epoxy to a graphite shaft?

The steps to apply epoxy are the same irrespective of whether you’re going to fix a steel shaft or a graphite shaft. Measure the tip of your old shaft. Trim the tip end of the new shaft following the trimming instructions so that it is the exact size of the old shaft. Roughen or abrade the shaft tip.

How much epoxy do you need for a golf club?

This will usually be less than 0.5g. A drop is more than enough for the shaft tip.

How to fix a broken golf club?

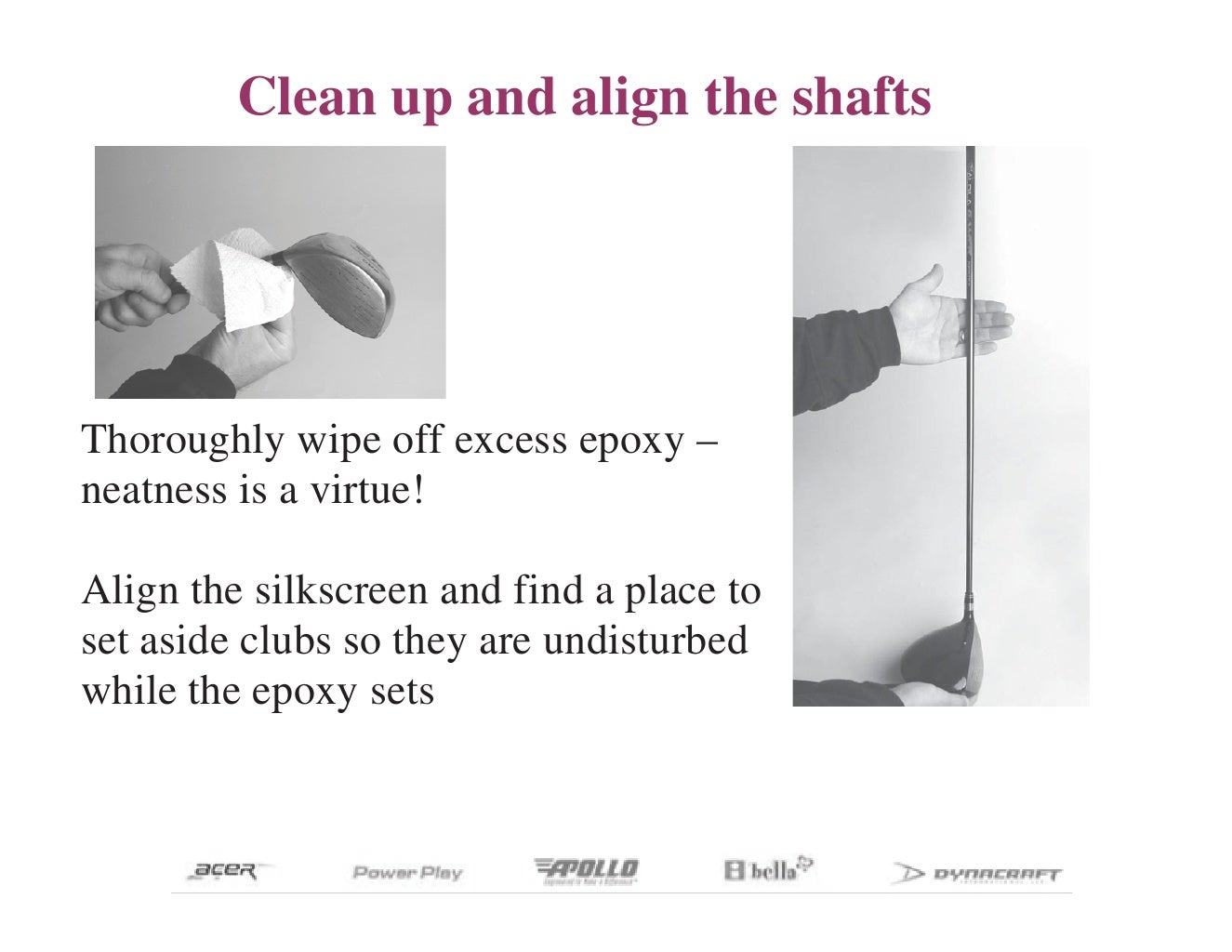

First remove the old epoxy from the hosel of the broken club. Use sandpaper and abrade the shaft tip that has to go into the club. Clean both the sealing surfaces using a solvent to remove any debris that may cause interference with the epoxy bond. Mix the epoxy components in a disposable container.

How much PSI should I use for golf shafting?

Ideally, your golf epoxy should have a PSI number of over 2500 PSI. The GolfWorks shafting epoxy is a great option because of its high torque resistance and shear strength. The epoxy renders 90% curing to 2765 PSI in a day and 100% curing to 3280 PSI in a week.

What is golf epoxy?

What is a Golf Club Epoxy? Golf epoxy is an organic compound that is used to repair and glue together broken parts of golf clubs. Epoxy is formed by a covalent bond between carbon and other elements like nitrogen, oxygen, or hydrogen. This is subject to curing in the presence of a catalyst to form an epoxy resin.

How to keep a shaft from getting burnt?

Keep the shaft in a super lock tight shaft holder and tighten it in a vise. If your shaft has a plastic ferrule, cover the ferrule with a wet paper towel so that it does not get burnt.

What is the process of hardening a material when it is exposed to chemical additives, heat, or air

This is subject to curing in the presence of a catalyst to form an epoxy resin. Curing is the process of hardening a material when it is exposed to chemical additives, heat, or air. The resin and curing conditions depend on the property and mechanical strength of the material the epoxy is applied to.

apexgrinds

Has anyone ever used epoxy from GolfWorks? I just installed a TM adaptor using their "high strength" epoxy (Not the tour or quick set stuff), and I'm a little concerned with how it has set up.

Socrates

Any time I see someone having sticky epoxy after setup should have taken place, I immediately think its either poor ratio, poor mixing or a combination of both.

gioguy21

i use JB weld and never had an issue. golfworks is overpriced for what it is.

Nessism

i use JB weld and never had an issue. golfworks is overpriced for what it is.

gioguy21

i use JB weld and never had an issue. golfworks is overpriced for what it is.

apexgrinds

Hmmm.....I'm quite OCD when it comes to this stuff. Swear the ratio was 1:1 and I mixed it for a long time.

Nessism

Hmmm.....I'm quite OCD when it comes to this stuff. Swear the ratio was 1:1 and I mixed it for a long time.

How long does it take to gel a golf club?

All the convenience and bonding strength of the standard Tour Set, but with a gel time of 25-35 minutes, allowing for more clubs to be done with one mix. Cures to playing strength in 60 to 90 minutes, depending on temperature.

What is the ratio of epoxy to TSP4?

For the TSP4 Tour Set Plus epoxy the mixing ratio is 1:1 whether you are mixing by weight or volume. These instructions are listed on the label on the bottles.